If you’re in Delhi and searching for the best distributor of AC200 Vector Control AC Drives, look no further than DS Automation & Controls. Known for their expertise and superior product quality, DS Automation & Controls is a trusted name in the field of industrial automation.

While maintaining excellent performance and functions, AC200 series products have been significantly improved in terms of ease of use, maintainability, environmental protection, installation space, and design standards from the perspective of customer applications.

1. Compact structure and easy to use.

2. Integration of driving synchronous and asynchronous motors.

3. High starting torque, open loop 0.5Hz 150%, closed loop 0Hz 200% rated torque.

4. High-frequency output, 12 times magnetic field weakening speed range, high precision output.

5. Excellent control performance.

6. Advanced motor self-learning function.

7. Extensive functions are abundant.

8. Simple debugging software.

1. Supports various types of motors/loads and can drive motors: ordinary asynchronous motors, variable frequency motors, AC servo motors, synchronous motors, high-speed motors and electric spindles.

2. Supports various types of motors/loads and can drive motors: ordinary asynchronous motors, variable frequency motors, AC servo motors, synchronous motors, high-speed motors, and electric spindles.

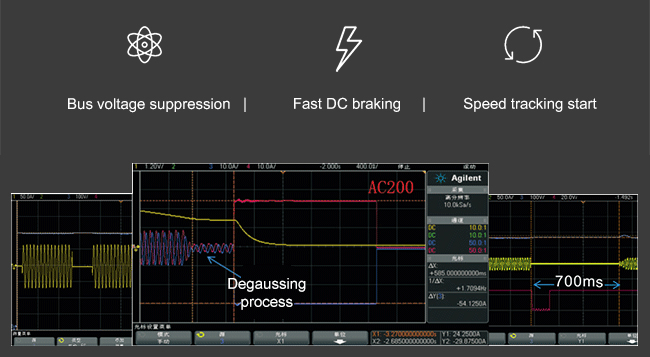

1. Excellent bus voltage suppression to avoid the over-voltage alarm when the inverter accelerates or decelerates too fast.

2. Fast DC braking, special software demagnetization processing, to ensure smooth and stable shutdown process without fluctuations.

3. The new generation of speed tracking start realizes zero waiting time and zero impulses current start.

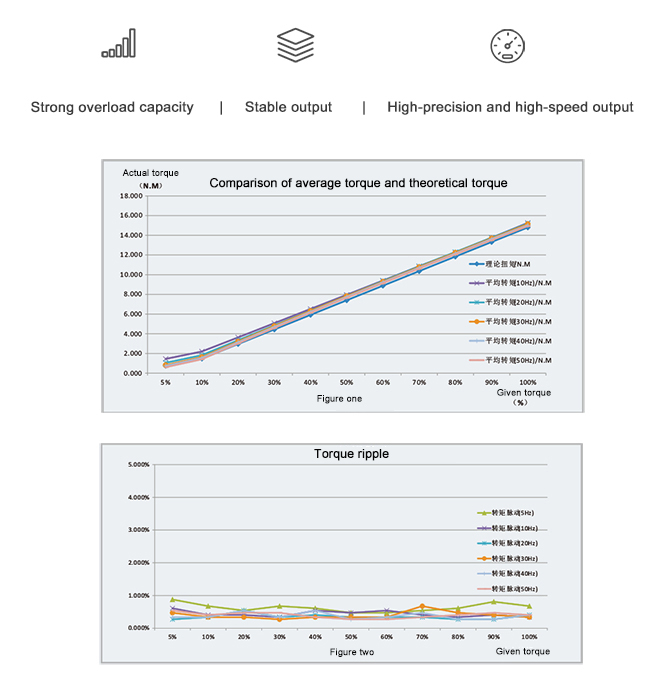

1. On the closed-loop vector mode, the torque linearity deviation is within 3%, the torque output is stable, and the low-frequency torque is large.

2. The output frequency under vector control is up to 600Hz, which can achieve high-precision speed output within 10 times the field weakening speed range.

3. Strong overload capacity, 60s at 150%, 10s at 180%, 0.5s at 200%.

4. Protect the torque limit and speed limit of the machine, and better protect the equipment safety under the premise of exerting the machine efficiency.

1. Motor parameter self-learning, static self-learning is comparable to dynamic self-learning, with no need to disassemble the load.

2. Instantaneous stop and non-stop, the inverter will not stop when the grid drops instantaneously, and the load will feedback energy to compensate for the voltage drop.

3. Coping with harsh environments more freely, the whole machine has a three-proof design, copper busbar plating, and PCB spraying three-proof paint.

1. Built-in multiple groups of PID function modules, diverse selection of given and feedback sources, simple and practical.

2. Abundant application functions, command channel switching, running command binding, timing, counter, and other functions.

3. The terminal functions are flexible and practical, switch analog quantity, high-speed pulse input, and output.

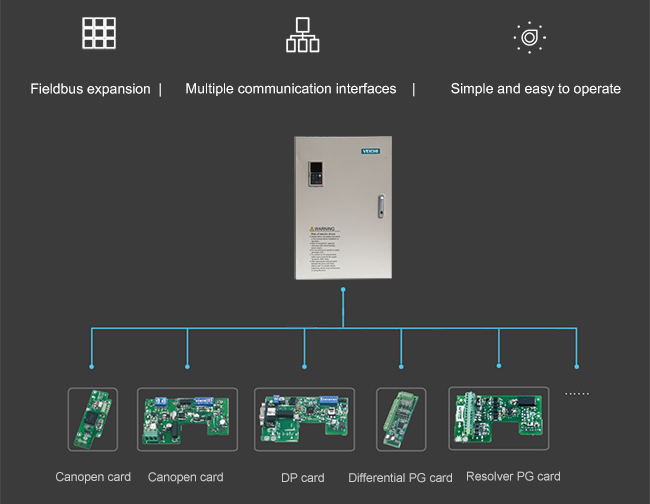

1. Support field bus expansion and PROFIBUS protocol can be supported through an optional DP card.

2. Provide a variety of communication excuses to realize RS485, DP, CAN, and CANopen communication.

3. IOT expansion card, high positioning accuracy, stable communication, compact and beautiful, easy to install.

4. PC software debugging, parameter rewriting, and monitoring, simple and easy to operate.

Applications:Fans and pumps, printing and packaging equipment, textile equipment, air compressors, injection molding machines, machine tools, and other industries and equipment.

When it comes to high-performance AC200 Vector Control AC Drives, DS Automation & Controls is the undisputed leader in Delhi. With their extensive inventory, technical expertise, and commitment to customer satisfaction, they provide unparalleled solutions for all your industrial automation needs.

If you’re looking to enhance efficiency and performance in your operations, connect with DS Automation & Controls today and discover the best in vector control technology.