When it comes to industrial motor control, frequency inverters play a crucial role in improving efficiency and reducing costs. Among the top frequency inverters available in India, the Veichi AC70 Series Frequency Inverter stands out as a game-changer. Designed with cutting-edge technology, it offers unparalleled performance across diverse industries.

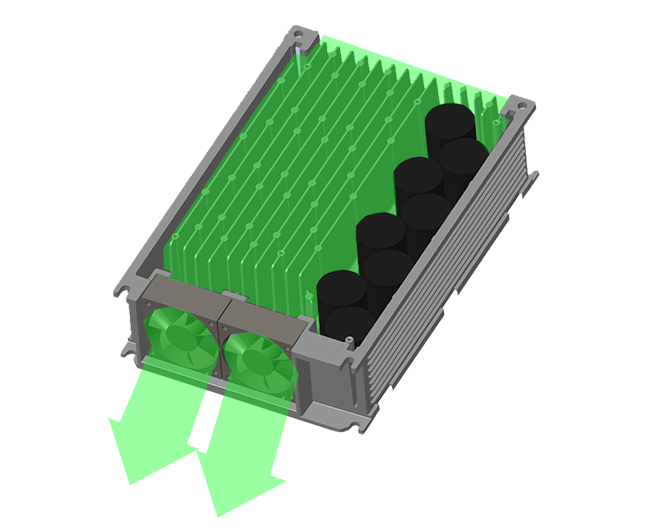

The Veichi AC70 Series Frequency Inverter series general-purpose inverter adopts an open-loop vector algorithm and modular design to realize high-performance and high-precision motor drive control. The product also has an independent air duct, which can effectively prevent dust from entering the circuit board. At the same time, the thickened three anti-paint protection makes it more environmentally adaptable.

1. High-performance open-loop vector control algorithm.

2. Flux algorithm, modular design.

3. Good grid adaptability and wide grid voltage range.

4. Abundant software functions to meet various needs.

5. High reliability and high environmental adaptability.

6. Easy to install, easy to debug, and easy to maintain.

7. Anti-dust, independent air duct design.

8. PCB board thickened with three anti-paint treatment.

1. V/F control: It is used for all variable speed controls that do not require fast response and high-precision speed control, and where multiple motors are connected with one inverter.

2. No PG vector control: used for all variable speed control, especially when high-precision speed control is required, the torque response is fast and the motor can also obtain a larger torque when running at low speed.

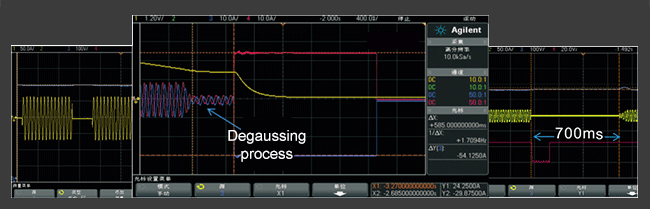

1. It has two self-learning methods of static/rotating to obtain accurate electrical parameters of the motor.

2. Under light load, one inverter can start with multiple motors to track and start, optimize the tracking function of software and hardware, and the accuracy of speed tracking is higher.

3. Effectively reduce the noise of the motor and suppress the interference of the inverter to external equipment.

4. There is no need to add peripheral braking resistors and other accessories to achieve a rapid braking effect, which can effectively suppress the rise of bus voltage during deceleration and avoid frequent overvoltage faults.

1. The new generation of energy-saving operation can realize the operation of the induction motor, and calculate the output voltage according to the load to achieve the purpose of energy-saving. It is mostly used on the occasion of energy-saving transformation.

2. The standard swing frequency is suitable for occasions where the swing frequency control is required for textiles and chemical fibers. The swing frequency amplitude, speed, and frequency can be set freely.

3. A variety of PID control, divided into ordinary PID and pressure closed-loop dedicated PID, wider application scope, and stronger industry pertinence.

1. To cope with sudden changes in load, the automatic current-limiting technology makes the frequency automatically adjusted to prevent the frequency converter from reporting faults frequently and affecting production efficiency.

2. Wide power grid voltage working range, professional “momentary stop, and non-stop” algorithm, to accurately compensate for the momentary power failure of the power grid.

3. Thickened PCB three-proof paint treatment: anti-moisture, anti-salt spray, anti-mold, and extend the life of the board.

1. Standard RS485 communication, support MODBUS-RTU, support PROFIBUS-DP communication protocol.

2. It is convenient to realize the connection between the upper computer and the PLC and realize remote monitoring.

1. The whole series of independent air duct design, the electronic components of 22KW, and below models are completely sealed and not windproof, effectively preventing pollutants from entering the electronic component area, improving the protective effect of the inverter, and adapting to various on-site environments.

2. The whole series adopts DC fans with long service life and easy replacement. It can be installed through penetration, more adaptable.

3. The cabinet machine adopts the upper and lower structure design, and the standard distribution reactor is installed in the base so that the heat dissipation effect is better, the service life of the whole machine is improved, and it is more reasonable and beautiful without limitation.

Applications:Fans and pumps, air compressors, wire drawing machines, injection molding machines, ball mills, machine tools, industrial washing machines, lifting industries, and other industries and equipment.

When it comes to frequency inverters, the Veichi AC70 Series Frequency Inverter stands out for its superior performance and efficiency. Partnering with DS Automation & Controls, the leading VEICHI dealer in India, ensures that you receive top-quality products and unparalleled support.

Whether you’re in manufacturing, water treatment, or HVAC, DS Automation & Controls is your trusted partner for industrial automation solutions. Contact them today to transform your operations with the VEICHI AC70 Series!