Program scan time of 1ms is implemented by increased instruction processing speed.

Real number operation and high-precision positioning control have been put to practical use by dramatically improved floating-point operation speed.

| SPH5000H | SPH3000(D) | SPH300 | SPH2000 | SPH200 | |

|---|---|---|---|---|---|

| Basic instruction LD | 6ns | 9ns | 20ns | 30ns | 70ns |

| MOV | 5ns | 8ns | 40ns | 40ns | 140ns |

| Floating Operation instruction | 66ns | 88ns | 80ns | 270ns | 56000ns |

*For details on each instruction word’s processing speed and tact cycle, see the User’s Manual (FEH200).

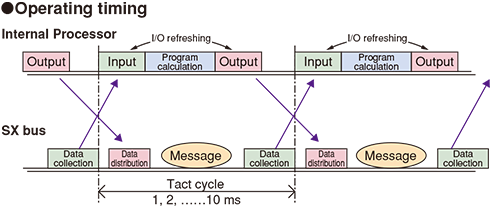

1024 points of I/O is refreshed in 1 ms.

Tact control assures a fixed I/O refresh interval. The I/O refresh cycle can be set to 1 ms, 2 ms, or up to 10 ms, which is suitable for processing requiring strict tact time.

The minimum tact times of SPH3000MM, SPH300, and SPH2000/SPH3000 can be set at 0.25 ms, 0.5 ms, and 1 ms, respectively.

| Tact cycle | 0.25ms | 0.375ms | 0.5ms | 1ms | 1.5ms | 2ms | |

|---|---|---|---|---|---|---|---|

| Max. I/O size (Number of I/O stations) | 4 stations | 67word | 256word | 512word | 2048word | 2048word | 4096word |

| 16 stations | – | – | 256word | 1024word | 1024word | 1024word | |

| 32 stations | – | – | – | 512word | 2048word | 2048word | |

| 64 stations | – | – | – | – | 512word | 1024word | |

| Tact cycle | 0.25ms | 0.375ms | 0.5ms | 1ms | 1.5ms | 2ms |

|---|---|---|---|---|---|---|

| Max. I/O size | – | – | 64word | 128word | 256word | 512word |

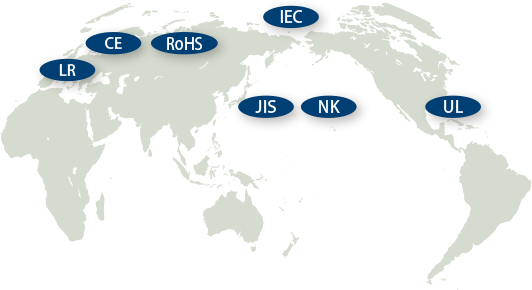

Both the hardware and software conform to the IEC 61131 international standard for programmable controllers.

The programming language conforms to the IEC 61131-3 international standard.

Conforms to the CE marking, UL standards and RoHS directive (conforming one after another) as well as IEC standard.

It also complies with the NK marine standard (Japan) and the LR (specifications of Lloyd’s Register of Shipping, UK).

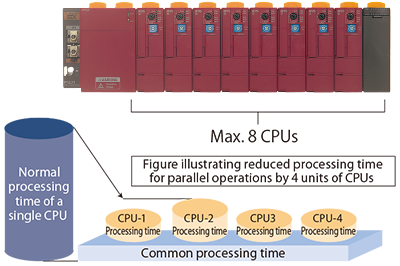

Alleviates the load for each CPU allowing high-speed processing of a large application program. For example, the load can be distributed for advanced processing and sequence control processing with additional CPUs. I/O refresh control is performed automatically even if parallel processing by multiple CPUs is performed.

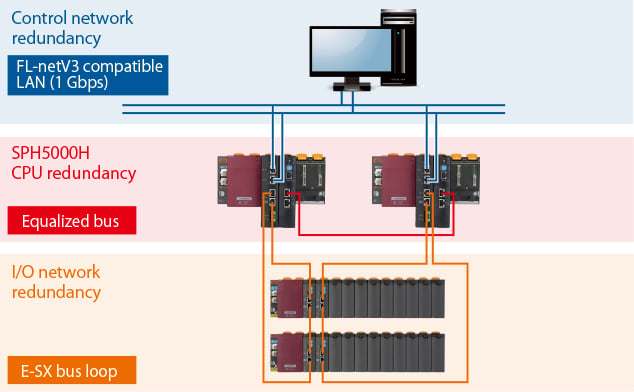

This redundancy configuration enables continued operation without system downtime if a CPU fails. (Control may temporarily stop due to fault detection and CPU changeover.)

The same program is stored in CPUs for the active and backup systems, allowing constant data value equalization.

N:1 backup feature enables reduction of the number of standby system CPUs to one, though when a CPU fails, data retained in the active system and that in the standby system are not equalized.

Data retained by the active system is not taken over. The backup system CPU performs initial start.

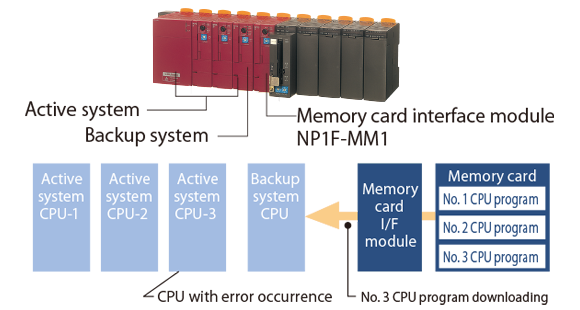

Programs can be intensively controlled by a memory card. Programs for N units of systems can be stored on a memory card, which is installed in the memory card interface module for centralized control of the programs. The same processing programs as on the down CPU are downloaded to the backup system CPU.

Note 1: The model that supports SPH2000 is NP1PM-256H.

Note 2: For a redundancy configuration buildup with a DC power supply, contact our sales section.

Allows you to construct control systems that support redundant CPU, duplexed control network, duplexed I/O network, and loop network.

| Function and performance | SPH3000(D) | SPH3000MM/MG/5000H | |

|---|---|---|---|

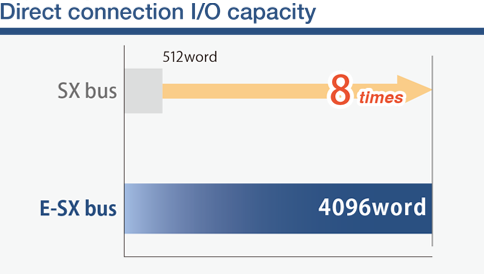

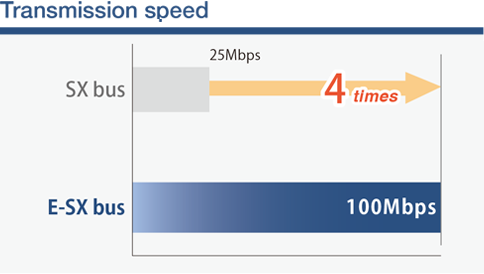

| System bus | SX bus | SX bus | E-SX bus |

| Direct connection I/O capacity | 512word | 512word | 4096word |

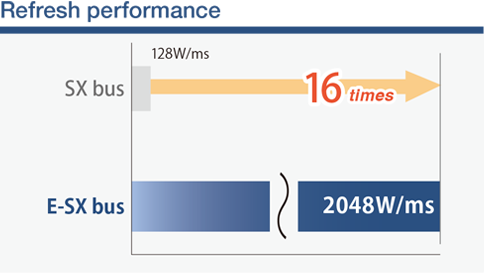

| Refresh performance | 128word/ms | 128word/ms | 2048word/ms |

| Transmission speed | 25Mbps | 25Mbps | 100Mbps |

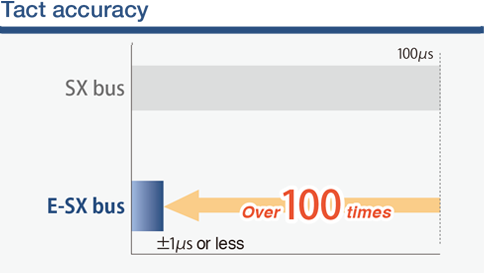

| Tact fluctuation | 100µs | 100µs | ±1µs or less |

| Synchronization between stations | None | None | Provided(±1µs or less) |

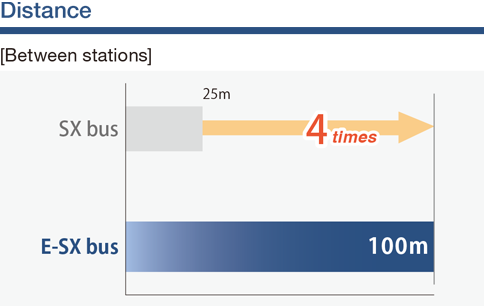

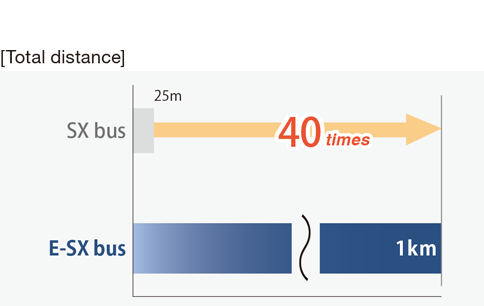

| Distance (between stations/total distance) | 25m/25m | 25m/25m | 100m/1km |

| Continued operation with the line broken (Loopback) | None | None | Provided |

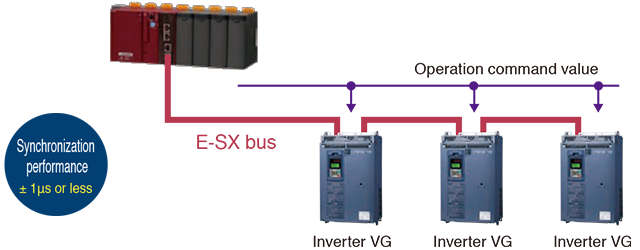

Data output timing is synchronized in the E-SX bus.

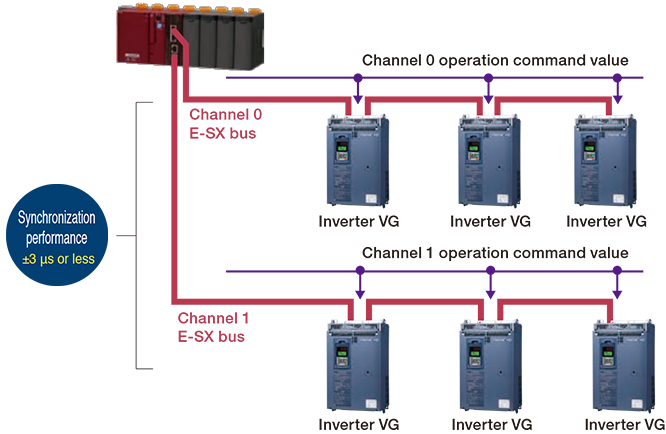

Data output timing is synchronized between channels of the E-SX bus.

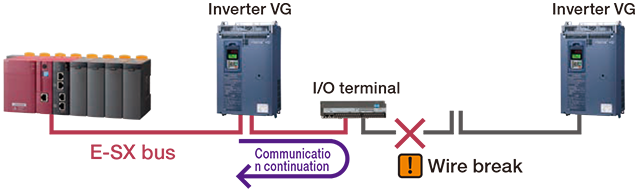

Communication is continued by the signal repeater function even when a wire is broken.

Even when a power of some devices is not turned on, the communication is continued by the auxiliary power unit.