Method to achieve high torque, high accuracy, high reliability and wide speed drive. Products built-in PLC, PID adjustment, programmable input and output terminals, RS485 interfaces, analog input and output, and other rich control functions. These functions provide highly integrated solutions for engineering and special industry automation applications.

1. Advanced design concepts and control algorithms.

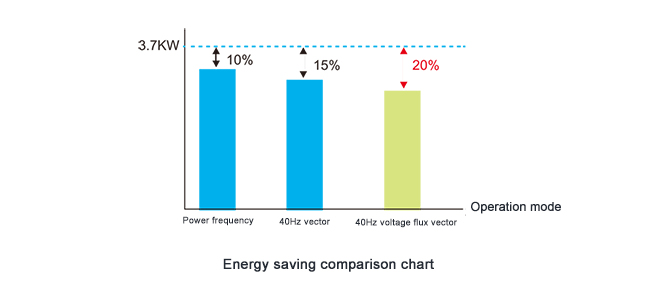

2. The energy-saving effect is good, and the power loss can be reduced.

3. Convenient operation, standard with potentiometer keyboard.

4. High performance-price ratio, rich functions, meeting different site requirements.

5. The compact structure layout saves installation space.

6. Reliable protective treatment and strong environmental adaptability.

7. Complete protection functions to avoid false alarms.

8. Low-power models, single-phase 2.2Kw, three-phase 4Kw.

1. Advanced control algorithm: vector control without PG, V/F control mode, optimized PWM output.

2. Humanized design and wide voltage input range to meet different field requirements.

3. Convenient operation, equipped with a keyboard with a potentiometer, plug and play, and support parameter copy.

4. Perfect fault protection, support historical fault record query, fast parameter copy.

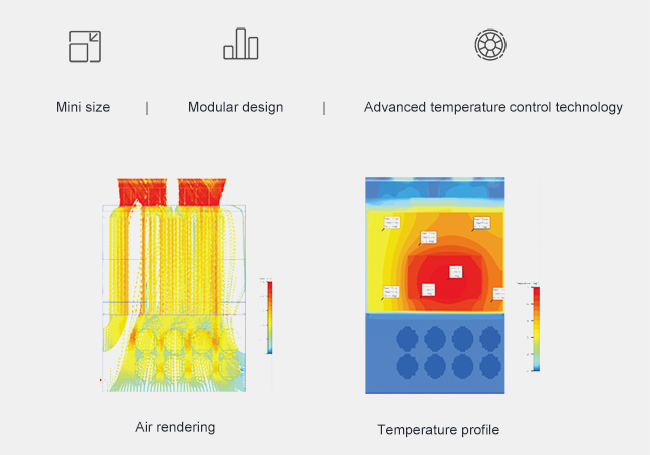

1. The mini size, compared with other series of the same power models, saves installation space.

2. Adopt advanced modular design concept, compact structure layout, professional thermal simulation design.

3. Strict and diverse thermal simulation ensures that the volume is reduced while the temperature rise of the whole machine is small.

1. The use of a new generation of energy-saving control technology can realize the operation of induction motors.

2. Reduce the excitation current according to the load current, and automatically adjust energy saving by the load condition.

3. Improve motor efficiency, reduce motor loss, and less energy loss.

1. The decoupling of the AC motor is truly realized, and the intentional vector control performance of the motor is realized. In the non-PG vector torque control mode, the torque control accuracy can reach 5%.

2. The motor runs in four quadrants, the torque, current, torque, and DC bus voltage respond quickly, and the motor runs stably.

3. Smart AVR function, when the voltage automatic adjustment function is effective, as long as the minimum value of input voltage fluctuation is greater than the set output voltage (motor rated voltage), the output voltage can basically maintain the set value.

4. The random carrier function can effectively reduce the noise of the motor and suppress the interference of the inverter to external equipment.

1. Two acceleration modes, four acceleration and deceleration times, the time unit is 0.1s, the longest is 6500s.

2. Simple PLC, automatic switching of running direction and frequency, to meet the requirements of on-site process.

3. The software speed tracking ensures that the motor is started and the current speed is started, effectively avoiding the motor reverse rotation.

4. DC braking provides leading torque, which is used to improve the stopping accuracy and realize fast stopping.

5. Jump frequency, automatically adjust the output frequency outside the resonance frequency.

1. Support derating operation of missing items and alarm of mechanical load damage.

2. The advanced drive algorithm controls the output voltage and current, reducing the frequency of inverter fault protection.

3. Overvoltage suppression. During deceleration, adjust the output frequency to avoid excessively high deceleration and cause the inverter bus voltage to be too high, thereby causing inverter overvoltage.

4. Over-current suppression. During acceleration, the output frequency is adjusted to avoid excessive load caused by excessive deceleration, which may cause an inverter over-current.

Application: Food machinery, Packaging machinery, Textile machinery, Automatic assembly line