As a leading dealer of Veichi All-rounder-AC310 Series Inverters in Delhi, DS Automation provides top-tier power solutions for both residential and industrial applications. The AC310 Series is engineered to offer optimal performance and energy efficiency, ensuring your operations run smoothly without interruptions. Whether you need a reliable inverter for home use or commercial purposes, the AC310 is built to meet the most demanding energy needs.

The Veichi All-rounder-AC310 Series Inverters series inverter is a product continuously developed on our latest high-performance vector platform. It adopts the international leading field-oriented vector control technology, continues to use the AC300 series book-style narrow-body design, modular hardware design, and has a wealth of expansion interfaces. Achieve high-tech performance, high reliability, high power density, high versatility, and other characteristics.

The Veichi All-rounder-AC310 Series Inverters series inverter can drive ordinary asynchronous motors, synchronous motors (including synchronous reluctance motors), spindle motors, torque motors, etc., and realizes the electric drive control that supports various loads, so it can adapt to various drive fields. Even if you change a different type of motor, you can save the trouble of replacing the driver.

Veichi All-rounder-AC310 Series Inverters series inverter also has a fan and water pump parameters, special parameters for tension control, special parameters for wire drawing machines, power balance parameters, quadratic load curve parameters, belt transmission parameters, punching machine parameters, machine tool parameters, and so on. Integrate multiple industries into integration, to avoid the trouble of customer selection.

From the application of the first fan and water pump product to the present, for more than ten years, our company has won the trust of customers with high quality, high-cost performance, and high efficiency.

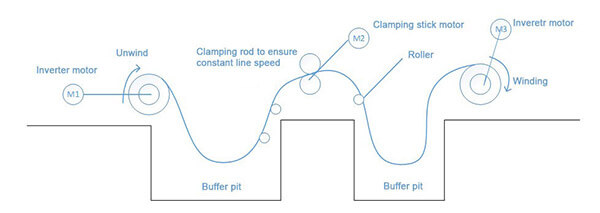

AC310 series inverter tension control is dedicated to keeping the tension constant through the control of the output torque and the automatic roll diameter calculation. There is no need to install a tension sensor, and no external feedback signal of the current position or current tension is required. In most applications, there is no need to install a speed feedback rotary encoder to accurately provide constant tension and ensure uniform thickness or thickness of the processed material.

The application of the AC310 series frequency converter in the wire drawing machine is a high-performance algorithm developed by combining our company’s years of application experience in the wire drawing machine industry. It can realize high-precision speed control and torque control of the motor, and meet the requirements of the wire drawing machine industry for inverter operation and control. With excellent performance, it has won the recognition and praise of wire and cable companies and welding wire manufacturers.

Advantages of AC310 series inverters in power distribution:

1. Ensure that the output of multiple motors is uniform. From the opportunity to adjust the output torque according to the load and host conditions, the output torque is consistent, so that the output power of each motor is consistent.

2. The power balance ensures that there will be no torsion between multiple motor shafts, thereby ensuring the life of the motor.

3. Power balance, as the name implies, is to ensure that the output power of each inverter drive motor is equal at all times, thereby eliminating the torque between the motors, no abnormal noise, and achieving perfect control. This process requires the inverter to respond quickly, accurately, and accurately.

AC310 series inverters have developed corresponding high-performance functions according to the characteristics of punching presses. While improving product reliability and environmental adaptability, it also strengthens customer ease of use and industry-specific design. More optimized functions, more flexible applications, more stable performance, richer interface resources, stronger expansion capabilities, and support for multiple communication interfaces.

AC310 series inverter application occasions cover almost all industries of industrial control. Faced with a society of diversified choices, you don’t have to worry about model selection, and you don’t have to worry about driver mismatch caused by replacing motors. VEICHI will eliminate all worries for you, and with your industrial growth, we will escort you with excellent reliability, strong application compatibility, and precise process control!