AC330 Series

AC330 Special Frequency Inverters

At DS Automation, we are proud to be the leading dealers of the VEICHI AC330 Special Frequency Inverters in Delhi. This inverter is designed for demanding industrial applications, offering precise frequency control and reliable performance. The VEICHI AC330 Special Frequency Inverters series ensures smooth operation for a variety of machinery, from pumps to HVAC systems, delivering energy-efficient and consistent power across various industries. Whether you’re powering high-performance equipment or need to regulate complex operations, the VEICHI AC330 is the ultimate solution.

AC330 Special Driver for Synchronous Reluctance Motor Overview

The VEICHI AC330 Special Frequency Inverters inverters are further optimized on the VEICHI AC310 product platform. Integrate the drive control concept of synchronous reluctance motor and develop a new vector control algorithm. Made a brand-new flux linkage observer. It has an excellent control effect in pure synchronous reluctance motor and permanent magnet auxiliary synchronous reluctance motor. At the same time, it is compatible with the control technology of asynchronous motors and permanent magnet synchronous motors. On the basis of ensuring the high reliability of the product, the software integration of the product is further improved, and the troubles of customers in product selection are better solved. With abundant expansion ports and comprehensive expansion accessories, it ensures the high reliability, high stability, and high adaptability of synchronous reluctance motor drive applications. VEICHI AC330 series inverters provide customers with better drive services with a new and full attitude.

AC330 features

1. Brand-new high-performance vector algorithm platform, dedicated drive for synchronous reluctance motor.

2. Ultra-efficient energy-saving drive.

3. Accurate torque excitation decoupling, excellent dynamic response performance.

4. Comprehensive thermal simulation design to ensure the rationality of hardware arrangement.

5. Full series of book design, saving installation space to the greatest extent.

6. Comprehensive expansion interface, rich selection of accessories, covering various applications.

7. Simpler and more convenient on-site debugging method, support on-site firmware upgrade.

8. The three-proof design of the whole machine and the three-proof paint of PCBA spraying ensure that the product is stable and reliable.

9. AC330 new EMC and grounding optimization, effectively solve electromagnetic interference.

10. Rich in expansion and reliable performance.

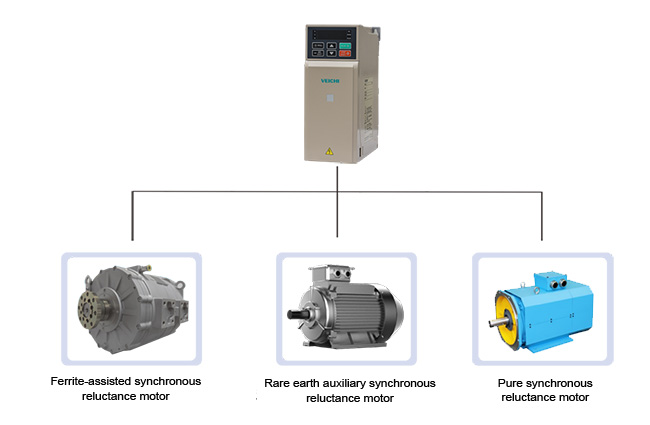

Dedicated for special inverter, compatible with drive

AC330 series products continue the AC310 book-type carrier design, retaining the original product structure characteristics. It is also committed to solving the drive application requirements of high-efficiency synchronous reluctance motors and has developed a new inductance parameter saturation learning function. The integrated drive multi-form synchronous reluctance motor can be compatible with more than 90% of the drive needs of the synchronous reluctance motor industry.

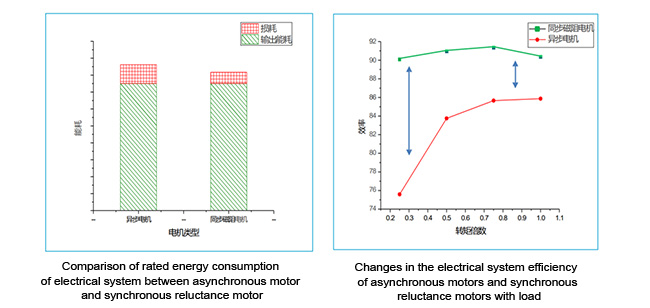

Better technology, energy saving and upgrade

AC330 series inverters have developed a new and optimized MTPA algorithm to adapt to the high-efficiency drive of synchronous reluctance motors in the market. The dq axis stator current can be optimally distributed to minimize the stator current, thereby minimizing the stator copper consumption and achieving the best electrical operation efficiency.

In addition, matching the new generation of energy-saving control technology can realize the efficient operation of induction motors. According to the load situation, it automatically adjusts energy-saving, two-pronged approach, maximizes the motor efficiency, and reduces energy loss.

Market test statistics compare asynchronous motors. Underrated conditions, the system loss of driving synchronous reluctance motors is reduced by about 40%, and the efficiency at the rated point is increased by about 5%. The load rate is less than 50%, and the energy-saving effect is particularly obvious.

Excellent low frequency characteristics

AC330 drive synchronous reluctance motor speed regulation ratio is 50:1 (when the synchronous reluctance motor rated frequency is 50Hz, 1Hz can drive full load). It can effectively make up for the insufficiency of the low-frequency drive of the synchronous reluctance motor. Ensure that the low-frequency operation of the electrical system is more stable, and the drive load capacity is stronger.

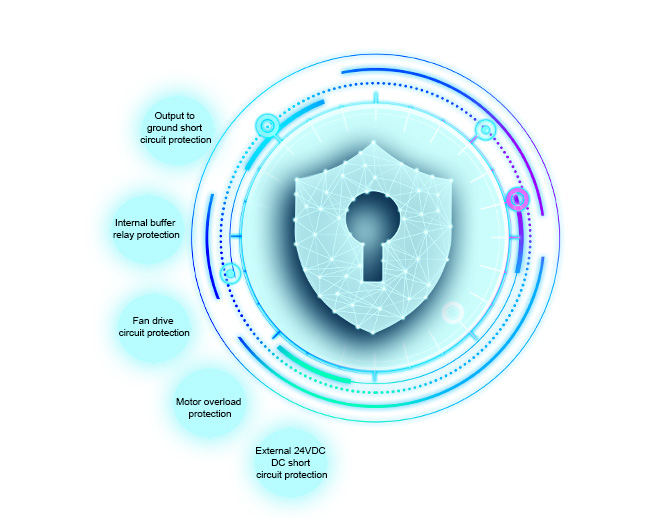

Comprehensive protection, stable and reliable

The AC330 series special drives are equipped with all-around protection of software and hardware for synchronous reluctance motors. It has the functions of output-to-ground short-circuit protection, internal buffer relay protection, fan drive circuit protection, external 24VDC short-circuit protection, and motor overload protection. Realize the full protection of the motor and peripheral equipment.

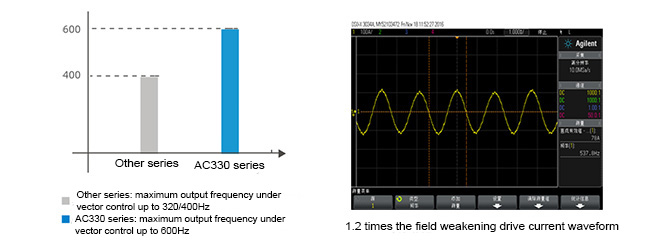

Excellent stability under weak magnetic field

The AC330 dedicated drive is equipped with a unique field weakening control algorithm above the base speed to maximize the use of voltage limits. In this way, the output torque is maximized, the constant power range is expanded, and the stability of operation under a weak magnetic field is guaranteed.

Expansion rich and comprehensive

AC330 series of special drivers for synchronous reluctance motors, with a variety of extended interfaces, to meet the needs of customization.

Two SPI high-speed channels are reserved on the product control board, which can support multiple expansion card selection applications at the same time.

Industrial Applications for AC330 Series Frequency Inverter

It can be used for plastic machinery, air compressors, machine tool spindles, textile machinery, pharmaceutical machinery and other light industrial machinery needs. It can also be used for fans, pumps, petroleum, chemical, paper making machinery, and other heavy machinery and equipment.

The Veichi All-rounder-AC310 Series Inverters series inverter is a product continuously developed on our latest high-performance vector platform. It adopts the international leading field-oriented vector control technology, continues to use the AC300 series book-style narrow-body design, modular hardware design, and has a wealth of expansion interfaces. Achieve high-tech performance, high reliability, high power density, high versatility, and other characteristics.

The Veichi All-rounder-AC310 Series Inverters series inverter can drive ordinary asynchronous motors, synchronous motors (including synchronous reluctance motors), spindle motors, torque motors, etc., and realizes the electric drive control that supports various loads, so it can adapt to various drive fields. Even if you change a different type of motor, you can save the trouble of replacing the driver.

Veichi All-rounder-AC310 Series Inverters series inverter also has a fan and water pump parameters, special parameters for tension control, special parameters for wire drawing machines, power balance parameters, quadratic load curve parameters, belt transmission parameters, punching machine parameters, machine tool parameters, and so on. Integrate multiple industries into integration, to avoid the trouble of customer selection.

Application of fan and water pump

From the application of the first fan and water pump product to the present, for more than ten years, our company has won the trust of customers with high quality, high-cost performance, and high efficiency.

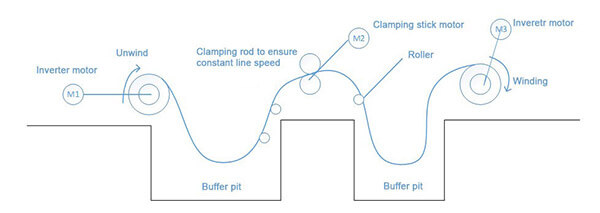

Application of tension control

AC310 series inverter tension control is dedicated to keeping the tension constant through the control of the output torque and the automatic roll diameter calculation. There is no need to install a tension sensor, and no external feedback signal of the current position or current tension is required. In most applications, there is no need to install a speed feedback rotary encoder to accurately provide constant tension and ensure uniform thickness or thickness of the processed material.

Application on wire drawing machine

The application of the AC310 series frequency converter in the wire drawing machine is a high-performance algorithm developed by combining our company’s years of application experience in the wire drawing machine industry. It can realize high-precision speed control and torque control of the motor, and meet the requirements of the wire drawing machine industry for inverter operation and control. With excellent performance, it has won the recognition and praise of wire and cable companies and welding wire manufacturers.

The use of power balance

Advantages of AC310 series inverters in power distribution:

1. Ensure that the output of multiple motors is uniform. From the opportunity to adjust the output torque according to the load and host conditions, the output torque is consistent, so that the output power of each motor is consistent.

2. The power balance ensures that there will be no torsion between multiple motor shafts, thereby ensuring the life of the motor.

3. Power balance, as the name implies, is to ensure that the output power of each inverter drive motor is equal at all times, thereby eliminating the torque between the motors, no abnormal noise, and achieving perfect control. This process requires the inverter to respond quickly, accurately, and accurately.

The use of punch

AC310 series inverters have developed corresponding high-performance functions according to the characteristics of punching presses. While improving product reliability and environmental adaptability, it also strengthens customer ease of use and industry-specific design. More optimized functions, more flexible applications, more stable performance, richer interface resources, stronger expansion capabilities, and support for multiple communication interfaces.

AC310 series inverter application occasions cover almost all industries of industrial control. Faced with a society of diversified choices, you don’t have to worry about model selection, and you don’t have to worry about driver mismatch caused by replacing motors. VEICHI will eliminate all worries for you, and with your industrial growth, we will escort you with excellent reliability, strong application compatibility, and precise process control!