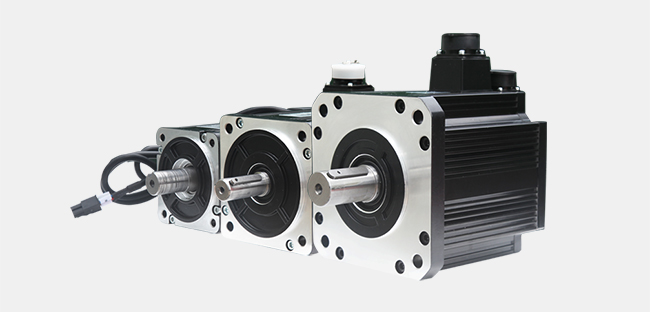

Precision, reliability, and performance are critical in the industrial automation world. It is achieved with the cutting-edge Veichi VM7 Series Servo Motor by DS Automation & Controls. We provides these motors to enhance existing systems or build new ones where motion control is needed. The servo motors are ideal for modern manufacturing, robotics, packaging, and CNC applications.

VEICHI VM7 Series Servo Motor is used together with the newly upgraded SD700 servo driver. Excellent performance design enables our motors to be widely used in various industrial fields, such as machine tools, packaging industry, industrial robots, and so on.

1. High-resolution encoder.

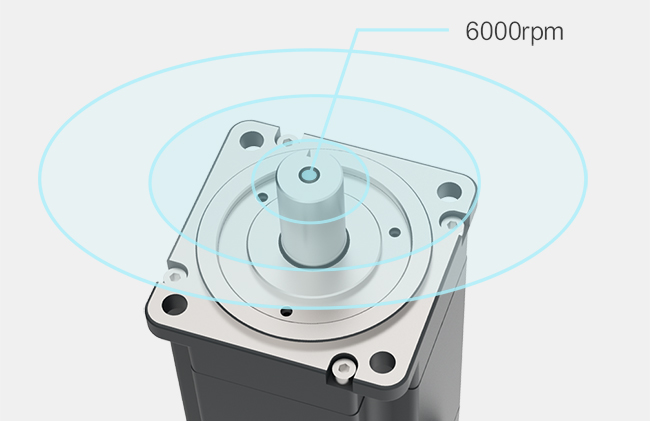

2. The high speed can reach 6000rpm.

3. Low noise and low vibration.

4. The heat dissipation is faster and the temperature distribution is more uniform.

5. High reliability and high stability.

6. 3~4 times overload capacity.

7. The volume is reduced by more than 20%.

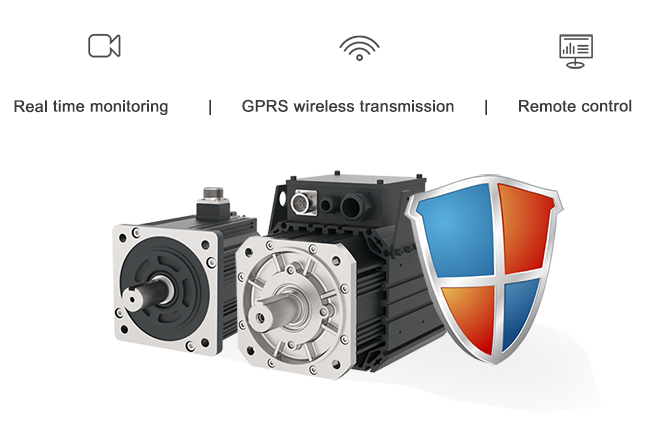

8. Protection grade IP65.

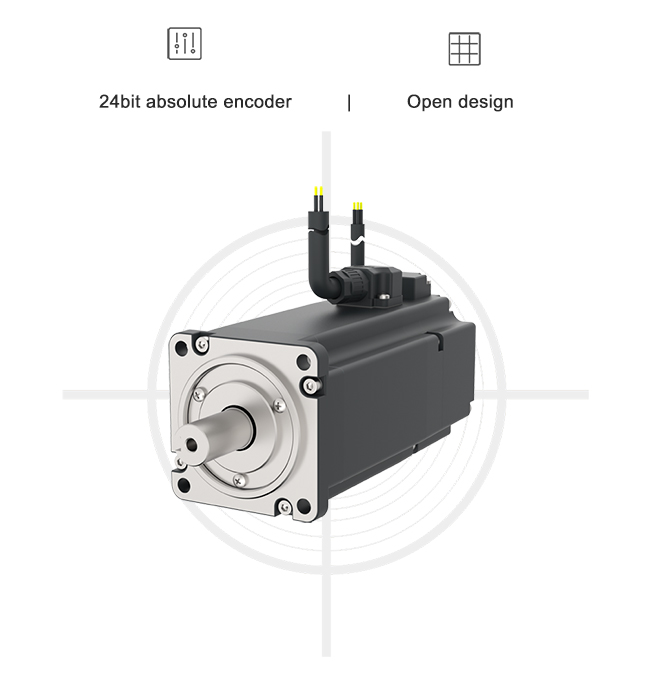

1. Standard 24Bit absolute value encoder.

2. The open design of the motor shaft end can be equipped with a variety of encoders, providing customers with multiple options.

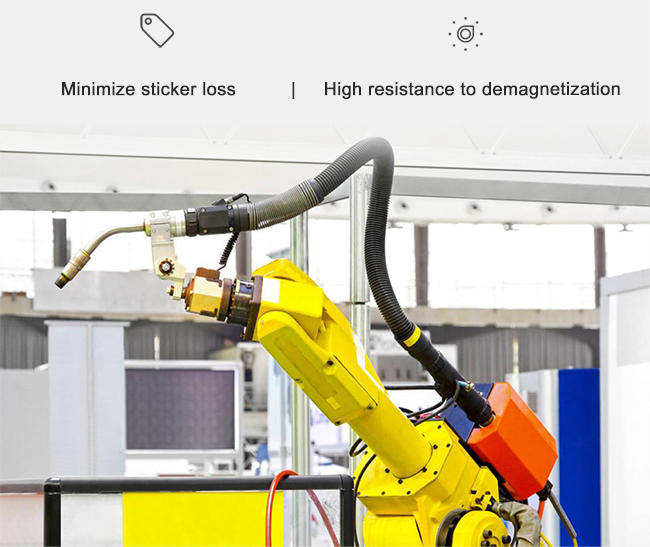

1. The stator punching piece and the rotor punching piece are made of Japanese Kawasaki high brand silicon steel sheet, which has a high magnetic load and minimizes sticking loss.

2. The use of ultra-high intrinsic coercivity permanent magnets has a high resistance to demagnetization.

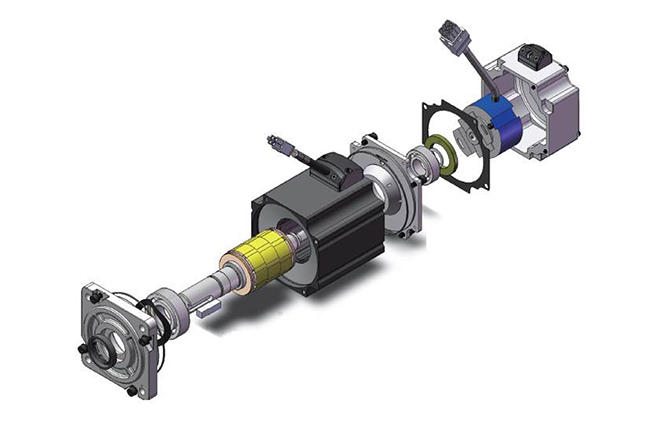

1. Optimized design of rotor with 10 stages.

2. Optimized design of stator with 12 slots.

3. Special cogging design can effectively suppress the cogging effect.

1. Maximum speed can reach 6000rpm.

2. Up to 3~4 times the overload capacity.

3. Low vibration, low noise, high reliability, and high stability.

1. Motor heat dissipation optimization design.

2. The full rate of the electrolytic cell is high, the winding diameter is large, the resistance is low, the heat is low, and the heat generation is reduced by 20%.

3. The protection grade is IP65, which greatly improves the environmental resistance.

Adopt brand-new manufacturing technology, optimize magnetic circuit design, reduce magnetic loss, and realize high dynamic response characteristics of the motor. Small size and lightweight, the motor volume is reduced by more than 20% compared with previous products.

Applications:Electronic manufacturing equipment, numerical control equipment, packaging machinery, printing machinery, textile machinery, plastic machinery and glass equipment, testing equipment, etc.

When precision, performance, and reliability matter, look no further than the Veichi VM7 Series Servo Motor from DS Automation & Controls. These motors are more than a product—they’re a performance upgrade for any automation system. With top-tier support, competitive pricing, and industry-leading quality, there’s no reason to settle for anything less.

Whether you’re streamlining a new production line or fine-tuning an existing one, the VM7 Series delivers the results that today’s industries demand.